| Oct 26, 2023 |

|

(Nanowerk Information) For the primary time ever, a joint analysis crew from the Korea Institute of Equipment and Supplies (KIMM) and the Korea Superior Institute of Science and Engineering (KAIST) has developed custom-made digital textiles utilizing graphene. The groundbreaking expertise was led by Principal Researcher Soongeun Kwon of KIMM’s Division of Nano Manufacturing Expertise and Professor Younger-Jin Kim from KAIST’s Division of Mechanical Engineering.

|

|

Their analysis was revealed in ACS Nano (“Multimodal E-Textile Enabled by One-Step Maskless Patterning of Femtosecond-Laser-Induced Graphene on Nonwoven, Knit, and Woven Textiles”).

|

|

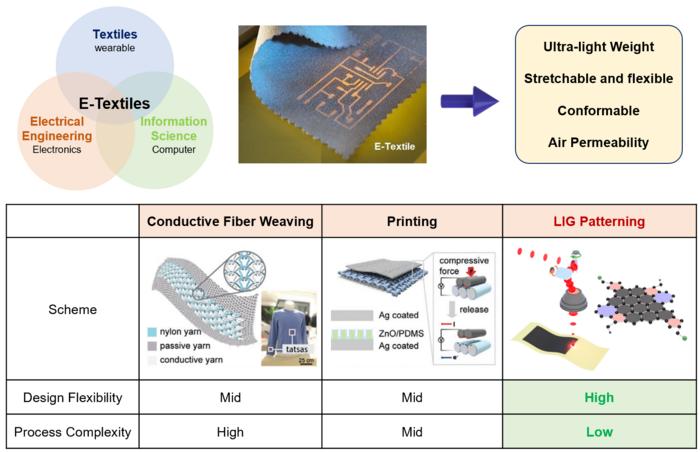

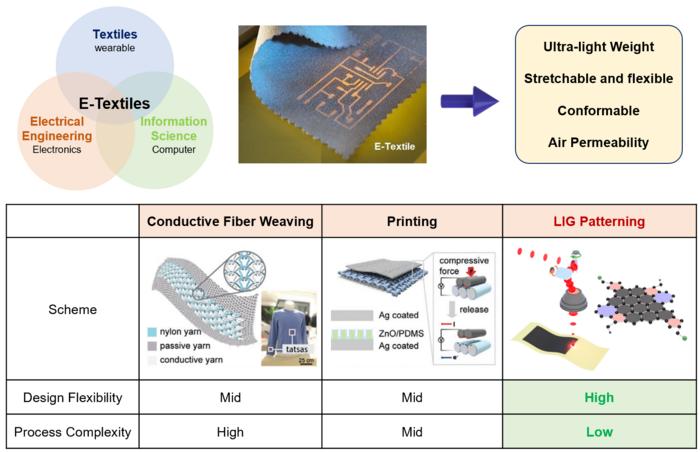

| (Above) Introduction on e-textiles and (beneath) comparability of strategies for manufacturing e-textiles. (Picture: Korea Institute of Equipment and Supplies)

|

|

This revolutionary method makes use of multimodal capabilities, which means it may possibly change data via varied sensory interfaces like visible and auditory sensations. What units this expertise aside is its methodology for creating patterns on textiles. Historically, electrically conductive textiles have been made by both coating materials with conductive ink or by attaching a skinny, useful layer onto generic materials. These strategies are cumbersome and infrequently contain using dangerous chemical substances, making them much less appropriate for mass manufacturing.

|

|

In a departure from these standard strategies, the crew used laser direct patterning expertise to create laser-induced graphene (LIG) on the material. This course of includes irradiating a high-power laser onto the floor of a garment, changing mild vitality into thermal vitality and instantaneously making a carbon materials just like graphene.

|

|

This distinctive course of ends in textiles with distinctive electrical conductivity, achieved via the applying of femtosecond laser processing expertise. This expertise makes use of ultra-short lasers, minimizing injury to the supplies and enabling high-resolution patterns.

|

|

The environmental advantages of this expertise are vital. As a result of it doesn’t require using poisonous chemical substances or further processing, these e-textiles will be manufactured in an eco-friendly method. The expertise opens up new prospects for creating industrial and army attire for private well being administration, in addition to customizable sensible garments within the healthcare sector.

|

|

Soongeun Kwon expressed the significance of this breakthrough, stating, “We’ve developed this expertise by learning the buildings of generic materials and remodeling them into graphene-based supplies with superior options. The strategy will not be solely eco-friendly but additionally conducive to mass manufacturing of custom-made e-textiles.”

|